| HEAD OF TEAM | : | Dwiwahju Sasongko, Ir., M.Sc., Ph.D |

| TEAM MEMBERS | : | Dr. Eng. Jenny Rizkiana, Dr. Winny Wulandari, Slamet Handoko ST, Hendi Aviano ST, Muhammad Afif Ridha ST |

| OFFICIAL ADDRESS | : | Laboratory of Design Methodology and Process Control, Chemical Engineering Program, ITB Ganesha Campus |

| : | sasongko@che.itb.ac.id | |

| EXTENDED ABSTRAct | : |

INTRODUCTION

Indonesia is one of biggest coal producer in the world. In 2014, Indonesia’s coal resources and reserves respectively 124.9 and 32.3 billion tons based on the data from Ministry of Energy and Mineral Resources Indonesia. However, around 70% of Indonesia’s coal resources and reserves are low rank coal with calorific value <5100 kcal/gr and has high moisture content (up to 30%) so it is inefficient to burn directly. In addition to inefficient, direct combustion of coal will cause emissions of CO2 that is not environmetally friendly.

Low rank coal upgrading can be done by co-pyrolysis with biomass waste. Indonesia is estimated to have the potential of biomass waste equivalent to more than 400 million GJ each year from agriculture, plantation, and forestry sectors. The co-pyrolysis process will produce new solid fuels called hybrid coal (Jeong et al., 2015; Lee et al., 2013; Park et al., 2010).

The purpose of this research is to study the effect of temperature, composition of the mixture, type of biomass waste used, as well as time of the co-pyrolysis process on hybrid coal yield. In the co-pyrolysis process, coal and biomass will undergo thermal decomposition at torrefaction and pyrolysis regime

METODOLOGY

The experiments were carried out using a vertical tubular furnace of 5 cm in diameter and 50 cm in length equipped with temperature controller to maintain the co-pyrolysis reactor at a given temperature. The furnace was connected to a nitrogen gas cylinder with pressure and flow regulator and provided with a rotameter to measure nitrogen gas flowrate. The original raw samples were Indonesian subbituminous coal, mahogany sawdust obtained from a furniture factory in Ciamis, and rice husk obtained from rice milling in Tasikmalaya, West Java. The experiment is divided into two parts. The variation of the first part of the experiment are biomass types (mahogany sawdust and risk husk); pyrolysis temperatures (200 °C, 300 °C and 400 °C); blend composition (15%, 22.5% and 30% mass of biomass waste) while the co-pyrolysis time is fixed at one hour. The variation of the second part of the experiment are blend composition (20%, 30% and 40% mass of biomass waste) and co-pyrolysis time (30 minutes, 60 minutes, and 90 minutes) while the biomass type and temperature are fixed, mahogany sawdust and 300 °C.

RESULTS

The experiment shows that the increase in retention time of co-pyrolysis from 30 to 90 minutes causing an increase in calorific value of 12.57-23.80%, or 23.68-26.05 kJ/gr. From the proximate analysis results, fixed carbon content rise with the increase of co-pyrolysis time. The highest fixed carbon content was obtained in the variation of 90 minutes, in the range of 49.36-49.75%. Increasing of sawdust content from 20 to 40%, lowering the calorific value in the range of 0.58-8.55%. Eight from nine samples of hybrid coals were successfully upgraded to bituminous coal based on its calorific value calculation. From theoretical calculation, hybrid coals produced lower non-neutral CO2 emission in the range of 22.63-44.35%. Interesting phenomena called synergistic effect occurs in co-pyrolysis mix of lignite and sawdust. In co-pyrolysis of low rank coal, synergies with biomass is found to happen easier when compared to co-pyrolysis of high rank coals because of the similarity between the structure of biomass with low rank coal (Quan and Gao, 2016).

Coal (raw material)

Coal (raw material)

Sawdust (raw material)

Sawdust (raw material)

Raw material position in the furnace

Raw material position in the furnace

Repolymerization of hybrid coal

Repolymerization of hybrid coal

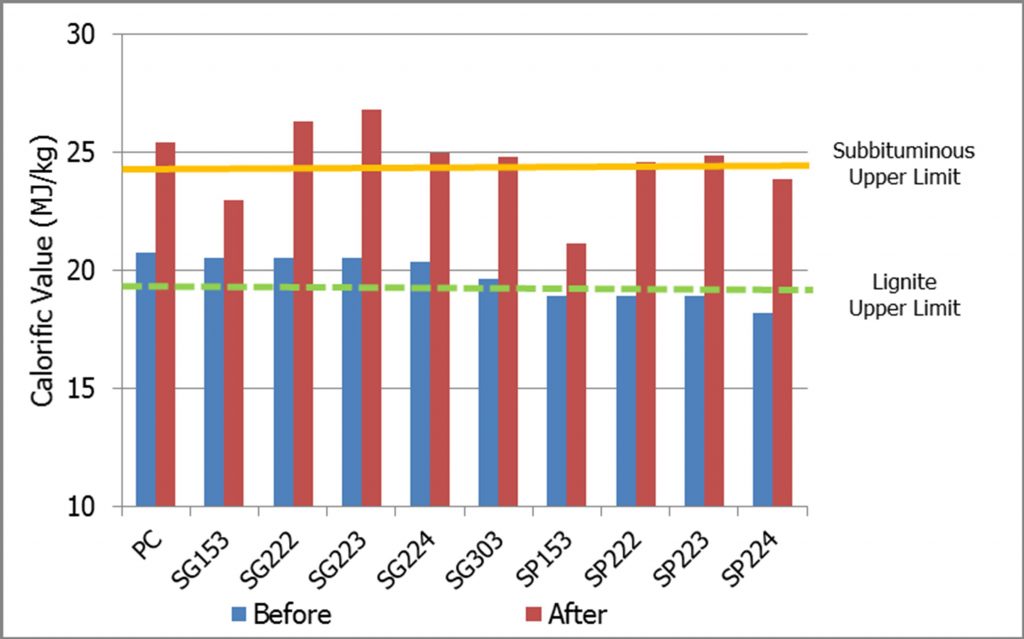

Increasing of calorific value after co-pyrolysis (1st experiment)

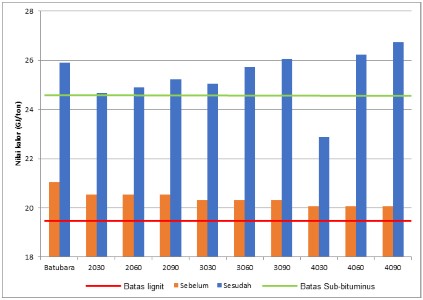

Increasing of calorific value after co-pyrolysis (2nd experiment)